Concrete Slump Test - Theory and Lab Test

Definition

- Slump is a measurement of concrete's workability, or fluidity.

- It's an indirect measurement of concrete consistency or stiffness.

A slump test is a method used to determine the consistency of concrete. The consistency, or stiffness, indicates how much water has been used in the mix. The stiffness of the concrete mix should be matched to the requirements for the finished product quality

Concrete Slump Test

The concrete slump test is used for the measurement of a property of fresh concrete. The test is an empirical test that measures the workability of fresh concrete. More specifically, it measures consistency between batches. The test is popular due to the simplicity of apparatus used and simple procedure.

Principle of Slump Test

The slump test result is a measure of the behavior of a compacted inverted cone of concrete under the action of gravity. It measures the consistency or the wetness of concrete.

Apparatus

- Slump cone,

- Scale for measurement,

- Temping rod (steel)

Procedure of Concrete Slump test:

- The mold for the slump test

- is a frustum of a cone, 300 mm (12 in) of height. The base is 200 mm (8in) in diameter and it has a smaller opening at the top of 100 mm (4 in).

- The base is placed on a smooth surface and the container is filled with concrete in three layers, whose workability is to be tested .

- Each layer is temped 25 times with a standard 16 mm (5/8 in) diameter steel rod, rounded at the end.

- When the mold is completely filled with concrete, the top surface is struck off (leveled with mould top opening) by means of screening and rolling motion of the temping rod.

- The mould must be firmly held against its base during the entire operation so that it could not move due to the pouring of concrete and this can be done by means of handles or foot - rests brazed to the mold.

- Immediately after filling is completed and the concrete is leveled, the cone is slowly and carefully lifted vertically, an unsupported concrete will now slump.

- The decrease in the height of the center of the slumped concrete is called slump.

- The slump is measured by placing the cone just besides the slump concrete and the temping rod is placed over the cone so that it should also come over the area of slumped concrete.

- The decrease in height of concrete to that of mold is noted with scale. (usually measured to the nearest 5 mm (1/4 in).

Precautions in Slump Test

In order to reduce the influence on slump of the variation in the surface friction, the inside of the mould and its base should be moistened at the beginning of every test, and prior to lifting of the mould the area immediately around the base of the cone should be cleaned from concrete which may have dropped accidentally.

Types Of Concrete Slump

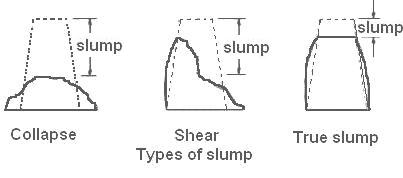

The slumped concrete takes various shapes, and according to the profile of slumped concrete, the slump is termed as;

- Collapse Slump

- Shear Slump

- True Slump

Collapse Slump

In a collapse slump the concrete collapses completely. A collapse slump will generally mean that the mix is too wet or that it is a high workability mix, for which slump test is not appropriate.

Shear Slump

In a shear slump the top portion of the concrete shears off and slips sideways. OR

If one-half of the cone slides down an inclined plane, the slump is said to be a shear slump.

- If a shear or collapse slump is achieved, a fresh sample should be taken and the test is repeated.

- If the shear slump persists, as may the case with harsh mixes, this is an indication of lack of cohesion of the mix.

True Slump

In a true slump the concrete simply subsides, keeping more or less to shape

- This is the only slump which is used in various tests.

- Mixes of stiff consistence have a Zero slump, so that in the rather dry range no variation can be detected between mixes of different workability.

Applications of Slump Test

- The slump test is used to ensure uniformity for different batches of similar concrete under field conditions and to ascertain the effects of plasticizers on their introduction.

- This test is very useful on site as a check on the day-to-day or hour- to-hour variation in the materials being fed into the mixer. An increase in slump may mean, for instance, that the moisture content of aggregate has unexpectedly increases.

- Other cause would be a change in the grading of the aggregate, such as a deficiency of sand.

- Too high or too low a slump gives immediate warning and enables the mixer operator to remedy the situation.

- This application of slump test as well as its simplicity, is responsible for its widespread use.

Degree of workability

|

Slump

|

Compacting

Factor

|

Use for which concrete is suitable

| |

mm

|

in

| |||

Very low

|

0-25

|

0-1

|

0.78

|

Very dry mixes; used in road making. Roads vibrated by power operated machines.

|

Low

|

25-50

|

1-2

|

0.85

|

Low workability mixes; used for foundations with light reinforcement. Roads vibrated by hand operated Machines.

|

Medium

|

50-100

|

2-4

|

0.92

|

Medium workability mixes; manually compacted flat slabs using crushed aggregates. Normal reinforced concrete manually compacted and heavily reinforced sections with vibrations.

|

High

|

100-175

|

4-7

|

0.95

|

High workability concrete; for sections with congested reinforcement. Not normally suitable for vibration

|

Table : Workability, Slump and Compacting Factor of concrete with 19 or 38 mm (3/4 or 11/2 in) maximum size of aggregate.

Difference in Standards

The slump test is referred to in several testing and building code, with minor differences in the details of performing the test.

United States

In the United States, engineers use the ASTM standards and AASHTO specifications when referring to the concrete slump test. The American standards explicitly state that the slump cone should have a height of 12-in, a bottom diameter of 8-in and an upper diameter of 4-in. The ASTM standards also state in the procedure that when the cone is removed, it should be lifted up vertically, without any rotational movement at allThe concrete slump test is known as "Standard Test Method for Slump of Hydraulic-Cement Concrete" and carries the code (ASTM C 143) or (AASHTO T 119).

United Kingdom & Europe

In the United Kingdom, the Standards specify a slump cone height of 300-mm, a bottom diameter of 200-mm and a top diameter of 100-mm. The British Standards do not explicitly specify that the cone should only be lifted vertically. The slump test in the British standards was first (BS 1881-102) and is now replaced by the European Standard (BS EN 12350-2).

No comments